Every workpiece and potting has its own requirements

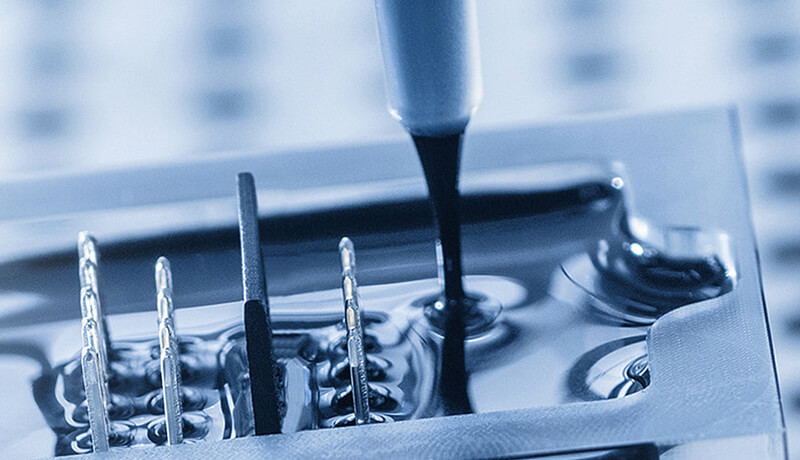

- Through glue viscosity analysis, determine whether the glue needs to be heated, and whether high - temperature - resistant materials are required for various seals.

- Through glue density and filler analysis, determine whether anti - wear materials are needed for spare parts and consumables.

- Through the analysis of various characteristics of the glue, select the optimal potting solution, whether it is vacuum potting or atmospheric pressure potting.

- Through glue sedimentation analysis, determine the cycle time and cycle interval of the equipment's circulation mode.

- Make arrangements for the operators in the outsourced production or have your company supply the workers.

- Ensure the optimal potting effect.

- Provide bonding, glue dispensing, and potting systems that meet your needs.

- Integrate upstream and downstream processes.

- Save more costs in small - batch production.

- Conduct trial production before mass production。

- Share the laboratory and offer free sample testing opportunities.

- Develop and set the process procedures for sample work-pieces.

- Provide preheating and curing of products.

- Offer options such as atmospheric pressure glue dispensing, vacuum glue dispensing, micro - glue dispensing, and large - volume glue dispensing.

- Provide professional advice and support from potting experts.

- The development simulation of the pre - production mode