HK DISPENSING

Huakong has been concentrating on the field of vacuum potting for 13 years

HK DISPENSING

Different system and solutions, We only provide the right system

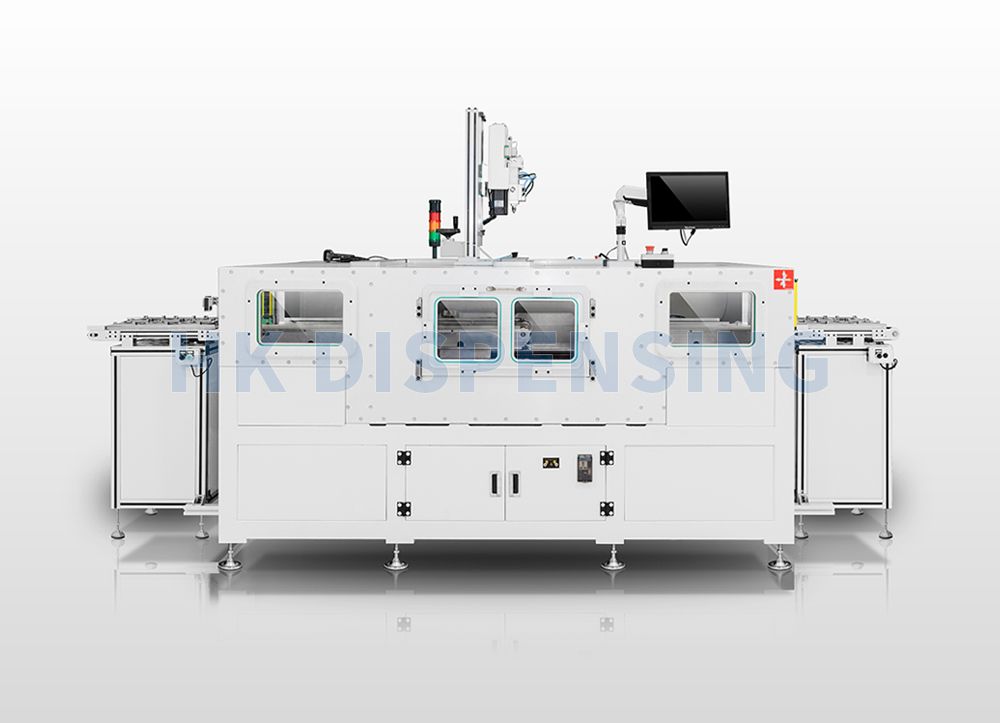

- Mitsubishi, BECKHOFF, DELTA system control

- By vacuum.the material preparation system protects the material hermetically against air or humidity and provide the ideal condition for bubble free casting. Minimum vacuum value is 2 mbar

- The material preparation system monitors the vacuum degree, temperature, and liquid level in real time

- Capacitive analog liquid level sensor

- No failures by accumulation due to the circulation of the material, also when the production is stopped ,sedimentation of particulate material can be reliable avoided

- The material barrel, supply piston pump, material pipe, dispenser, and mixing tube are all heated to a constant temperature.

- Mitsubishi, BECKHOFF, DELTA system control

- By vacuum.the material preparation system protects the material hermetically against air or humidity and provide the ideal condition for bubble free casting. Minimum vacuum value is 2 mbar

- The material preparation system monitors the vacuum degree, temperature, and liquid level in real time

- Capacitive analog liquid level sensor

- No failures by accumulation due to the circulation of the material, also when the production is stopped ,sedimentation of particulate material can be reliable avoided

- The material barrel, supply piston pump, material pipe, dispenser, and mixing tube are all heated to a constant temperature.

- Mitsubishi, BECKHOFF, DELTA system control

- By vacuum.the material preparation system protects the material hermetically against air or humidity and provide the ideal condition for bubble free casting. Minimum vacuum value is 2 mbar

- The material preparation system monitors the vacuum degree, temperature, and liquid level in real time

- Capacitive analog liquid level sensor

- No failures by accumulation due to the circulation of the material, also when the production is stopped ,sedimentation of particulate material can be reliable avoided

- The material barrel, supply piston pump, material pipe, dispenser, and mixing tube are all heated to a constant temperature.

- Mitsubishi, BECKHOFF, DELTA system control

- By vacuum.the material preparation system protects the material hermetically against air or humidity and provide the ideal condition for bubble free casting. Minimum vacuum value is 2 mbar

- The material preparation system monitors the vacuum degree, temperature, and liquid level in real time

- Capacitive analog liquid level sensor

- No failures by accumulation due to the circulation of the material, also when the production is stopped ,sedimentation of particulate material can be reliable avoided

- The material barrel, supply piston pump, material pipe, dispenser, and mixing tube are all heated to a constant temperature.

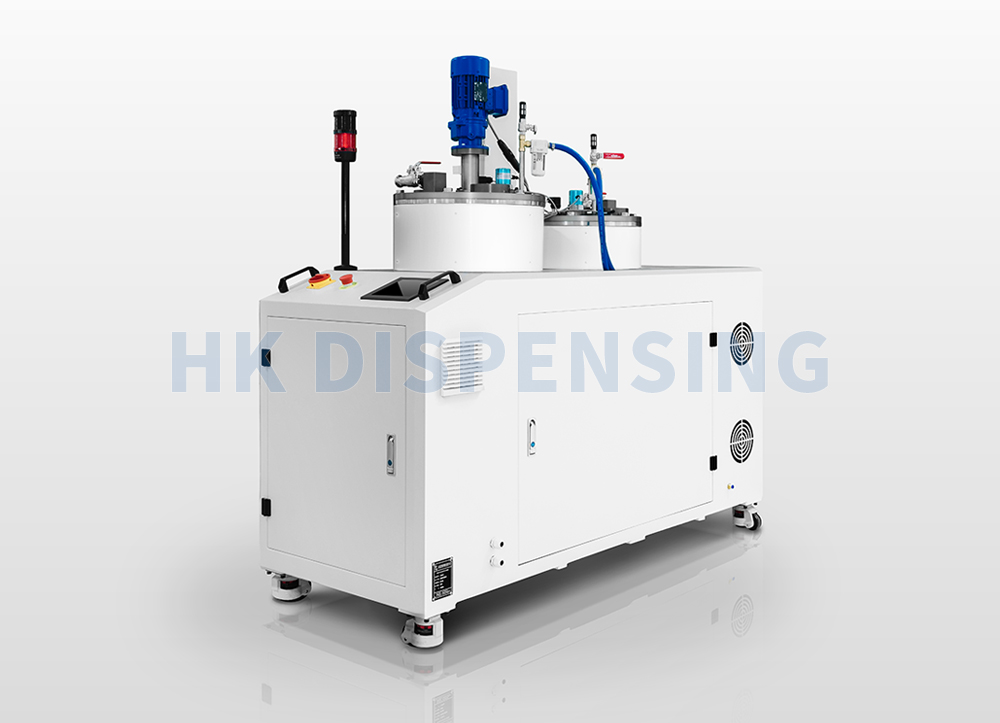

- Fully automatic control

- Real-time PID monitoring and control

- Monitors the liquid level in real time

- Handling high filler and high viscosity adhesives with a maximum viscosity of 500,000 cps

- Processing thermally conductive silicone grease with a maximum density of 3.2g/ml

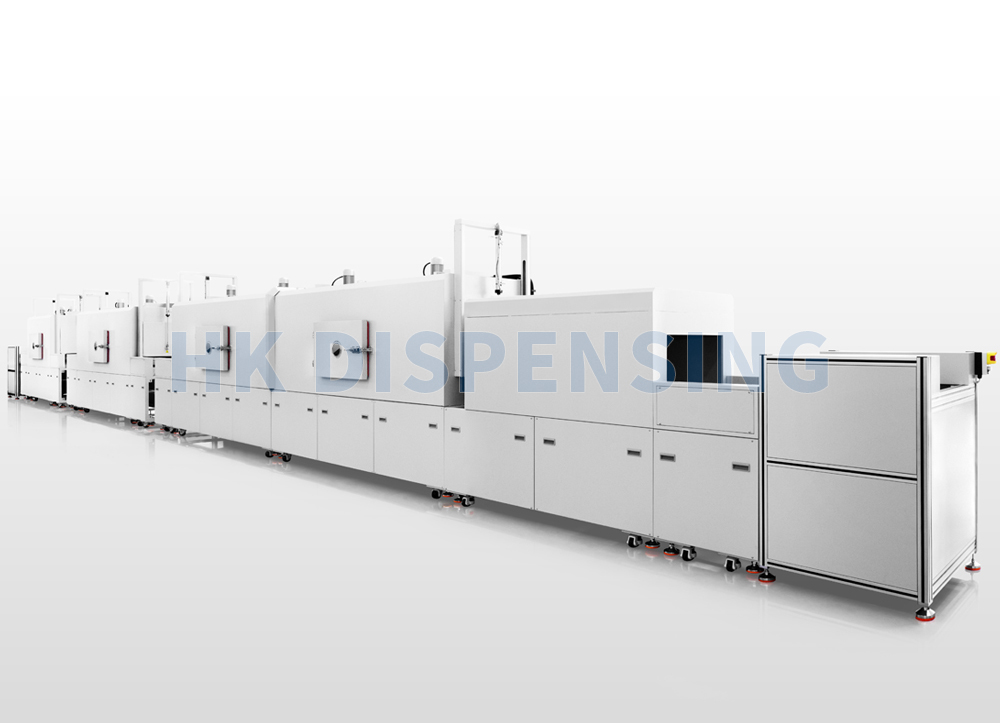

- Controlled by Mitsubishi or DELTA systems

- The maximum temperature can reach above 150°C

- Temperature fluctuation within ±3°C

- Heat - insulated and heat - preserved, with the outer shell temperature not exceeding room temperature + 5°C

- Non - standard customized multi - layer and multi - track design

- Automatic reflow