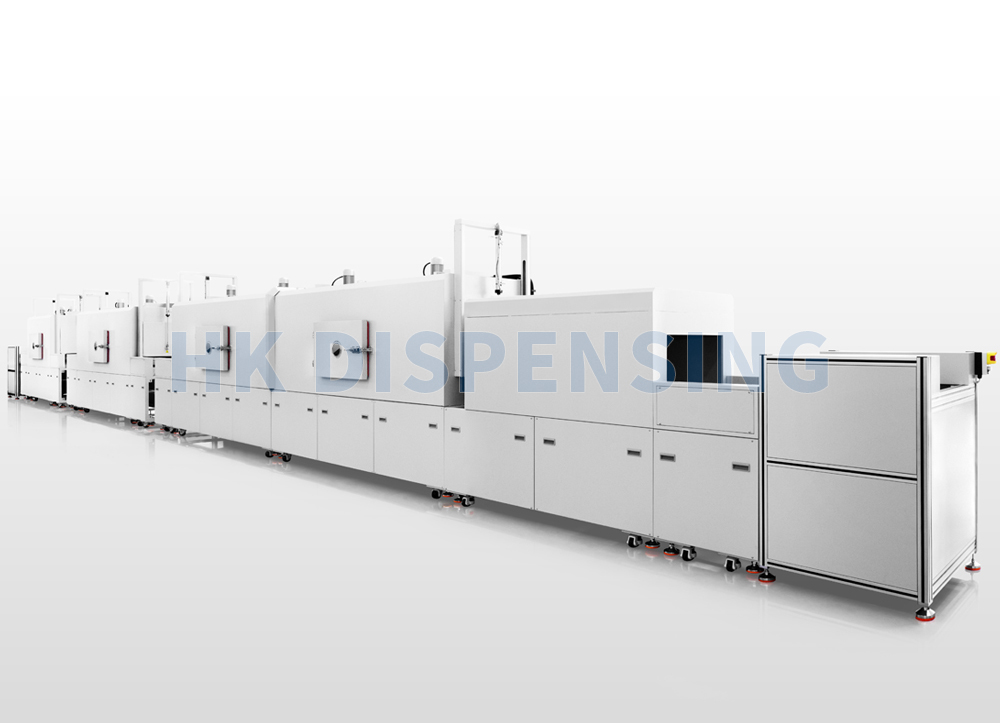

| Product Name | Tunnel Oven |

| Temperature Range | The heating temperature can be adjusted from room temperature to 130°C |

| Temperature Fluctuation Degree | ≤+3℃ |

| Oven temperature difference | Test in the constant temperature state ≤±3℃ |

| Heating-up rate | <8℃/Min |

| Outer shell temperature | The temperature rise does not exceed the environment + 5°C, except for the surrounding joints |

| Hot air circulation mode | Air outlet at the bottom of both sides and air return at the top |

| Power supply | Three-phase five-wire system,380V,50HZ |

| Outer shell requirements | The outer shell is made of 2.0mm thick cold – rolled plate, with high – temperature electrostatic spraying on the surface, which is corrosion – resistant and rust – proof. Adjustable feet and movable castors are equipped at the bottom. |

| Inner Chamber Material | 1、Made of 1.5mm thick SUS304 stainless steel plate 2、Keep the inner tank clean and dust – free, rust – proof, and corrosion – resistant |

| Furnace Body Underframe | Made of square steel to maintain the bearing strength of all surfaces inside and outside the furnace body and retain the coefficient of thermal expansion and contraction, which can prevent the furnace body from deforming. |

| Over – temperature Protection Thermostat | An imported temperature module is used. When the temperature exceeds the set value of the over – temperature protection thermostat, the heating power supply is automatically cut off |

| Power | Designed and configured according to actual needs |