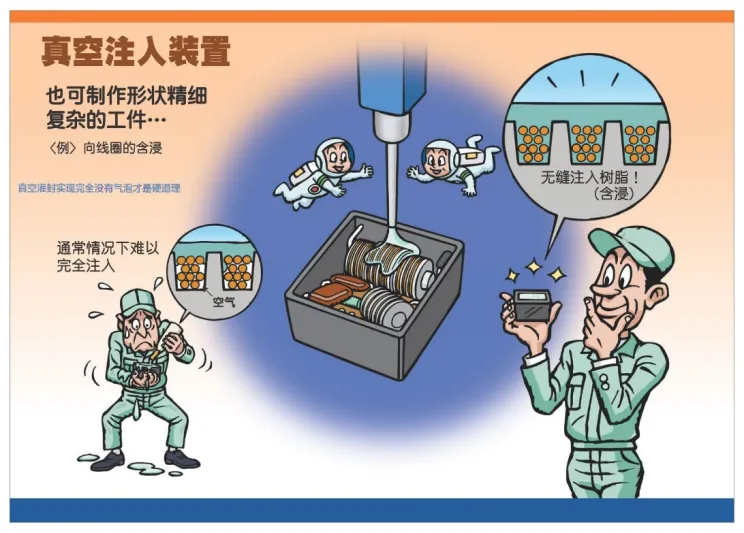

A vacuum glue dispensing machine is a device that dispenses glue in a vacuum environment. The biggest difference compared with ordinary glue dispensing machines lies in the vacuuming aspect, which directly affects the quality of products.

The main application industries include automobile manufacturing, capacitor coil glue dispensing, etc. At the same time, the equipment has good recyclable working ability, which improves production efficiency.

The vacuum glue dispensing machine, on the basis of an ordinary glue dispensing machine, evacuates the air in the pipeline pump body to prevent foaming.

If there are still bubbles in the resin dispensed by the fully automatic vacuum glue dispensing machine, it may be due to the following reasons:

-

The vacuum pump equipped with the glue dispensing machine is not effective and cannot remove the bubbles.

-

The glue dispensing machine does not evacuate and defoam the resin before dispensing the glue.

-

The resin glue has high viscosity, and the method of evacuating and defoaming needs to be improved.

-

It is related to the glue and requires secondary defoaming.

Characteristics of the vacuum glue dispensing machine:

-

Accurate positioning, high precision, small operation error, and the use of double-layer linear slides and high-precision balancing devices.

-

A powerful electronic control system: using imported original motors, PLCs, touch screens. The electronic components, wiring, dust-proof and anti-static systems all meet standards superior to those of the industry.

-

Accurate glue mixing: Selecting high-precision piston pumps, with a glue output ranging from 0.05 to 5000.00 ml. Equipped with a liquid level alarm function for glue A and glue B, it can timely prevent the occurrence of glue interruption. A glue volume monitoring module can be optionally configured for glue A and glue B to prevent the problem of glue not drying caused by the interruption of glue A and glue B.

-

Multiple filtration systems: From the glue barrel to the glue dispensing head, the glue is filtered multiple times to prevent impurities from entering the glue barrel and causing the pump to get stuck.

-

A heating device can be added, and a stirring device for glue A is equipped to prevent precipitation.

-

Easy to clean: The machine adopts a separate liquid dispensing method and mixes only at the glue dispensing head. After use, the mixing tube can be removed and soaked in the cleaning solution or directly cleaned.

-

Integrated design of glue mixing and glue dispensing, which can be used immediately after being mixed, and is fully automatically operated.

-

Simple to operate, it can store 1000 groups of formulation programs. During production, the product parameters can be retrieved, and just press the start button.

-

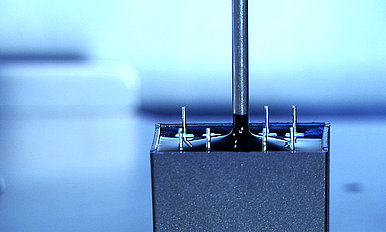

The vacuum glue dispensing machine uses thickened tempered glass as the viewing window, and all joints are sealed with sealing rubber strips to ensure the vacuum environment for glue dispensing.