The vacuum glue dispensing process is an automatic glue dispensing operation method that ensures the product is under absolute negative pressure. The product is placed in a vacuum chamber, and then the air in the vacuum chamber is removed to make the vacuum chamber reach a negative pressure state. After that, the mixed AB glue is automatically poured into the product, which is the “vacuum glue dispensing process”. It is mainly suitable for processes such as glue dispensing, potting, filling, and dripping that have high defoaming requirements. It is mainly applied in fields such as communication, precision electronics, automotive electronics, various accessories, capacitor coils, motor coils, sensors, transformers, relays, motors, high-voltage power supplies, etc. At the same time, the equipment has good recyclable working ability, which improves production efficiency.

The vacuum glue dispensing process is mostly used to solve the problem of bubbles during glue dispensing.

First, understand the concept of bubbles. Bubbles during glue dispensing are divided into physical bubbles and chemical bubbles. Physical bubbles refer to the bubbles generated during the process when the glue is in contact with air after being opened from the barrel. Chemical bubbles refer to the air in the gaps between the molecules inside the glue, and the tiny bubbles gradually generated during the reaction of the glue.

First, understand the concept of bubbles. Bubbles during glue dispensing are divided into physical bubbles and chemical bubbles. Physical bubbles refer to the bubbles generated during the process when the glue is in contact with air after being opened from the barrel. Chemical bubbles refer to the air in the gaps between the molecules inside the glue, and the tiny bubbles gradually generated during the reaction of the glue.

Solving a large number of bubbles generated after glue dispensing (generally referring to physical bubbles)

Currently, many products are glued in an atmospheric environment. The glue dispensing machine is equipped with a vacuum pumping function in the AB glue barrel, so that there will be no bubbles inside the glue dispensing machine. In most cases, this can already meet the requirements of glue dispensing production.

Currently, many products are glued in an atmospheric environment. The glue dispensing machine is equipped with a vacuum pumping function in the AB glue barrel, so that there will be no bubbles inside the glue dispensing machine. In most cases, this can already meet the requirements of glue dispensing production.

However, for some manufacturers, after the glue barrel is vacuumed, there are still a large number of bubbles after normal glue dispensing, and these bubbles cannot be discharged by themselves. This situation is the bubbles generated after the glue dispensing action, which are generated in the process of the glue being dispensed from the mixing tube and poured into the product. Using vacuum glue dispensing equipment can solve this problem.

A small number of bubbles hidden inside the glue (generally referring to chemical bubbles)

The original design intention of some electronic products is to serve throughout the entire service life and be non-repairable. If such products are glued in a natural atmospheric pressure environment, there will be a few bubbles hidden inside the glue. After a certain period of use, the probability of product failure will increase. The failure usually does not occur quickly and may occur after several months or years of use. The vacuum glue dispensing machine can provide quality assurance for encapsulated and glued products with such hidden risks.

The original design intention of some electronic products is to serve throughout the entire service life and be non-repairable. If such products are glued in a natural atmospheric pressure environment, there will be a few bubbles hidden inside the glue. After a certain period of use, the probability of product failure will increase. The failure usually does not occur quickly and may occur after several months or years of use. The vacuum glue dispensing machine can provide quality assurance for encapsulated and glued products with such hidden risks.

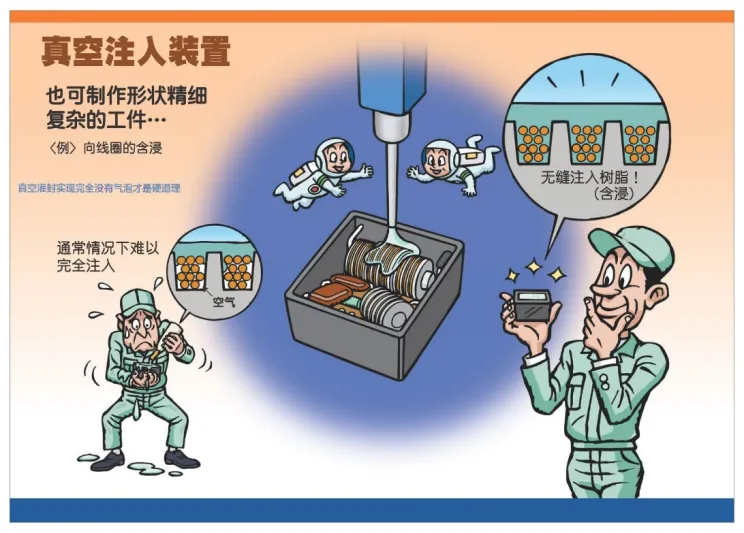

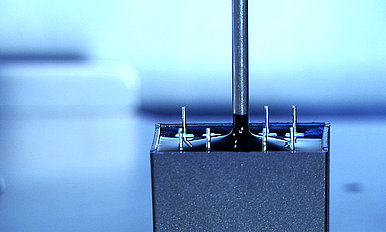

To make the glue better penetrate into the gaps of the product

For the two-component AB glue used by some manufacturers, when the structure of the product that needs to be glued is relatively precise and complex, it is difficult for these glues to penetrate and fill all the gaps of the product. Glue dispensing in a vacuum state can help the glue effectively and naturally penetrate into all the gaps.

For the two-component AB glue used by some manufacturers, when the structure of the product that needs to be glued is relatively precise and complex, it is difficult for these glues to penetrate and fill all the gaps of the product. Glue dispensing in a vacuum state can help the glue effectively and naturally penetrate into all the gaps.

The function of eliminating bubbles using the vacuum glue dispensing process

As mentioned earlier about the impact of bubbles on the product, using a vacuum glue dispensing machine can make the glue filling homogeneous, and after curing, the consistency is better, and the inside of the product is completely filled without bubbles. This method can better ensure the product quality.